list the different types of indenters used in hardness testing|what is indentation hardness : exporters What is indentation hardness testing? The most basic and commonly used definition is the resistance of a material to permanent, plastic deformation. It is measured by loading an . web283 linhas · Ranking Conmebol de la Copa Conmebol Libertadores y Sudamericana. Actual ranking oficial: Actualizado al 18 de diciembre de 2023: 6 . Ranking por federaciones. Top 6 en cada país. Referencias (actualizadas al 22 de diciembre de 2022 .

{plog:ftitle_list}

32K Followers, 289 Following, 102 Posts - See Instagram photos and videos from Luuuh Barbosa (@luuhbarbosaoficial)

There are two types of indentation hardness test. The first type (Brinell and Vickers) measures the size of the impression left by an indenter of prescribed geometry under a known load . In this article, we want to look into the four different methods of indentation hardness testing methods. Rockwell Hardness Testing. First developed over one hundred .Brinell testing uses larger indenters (e.g. 10 mm) and heavier loads (e.g. 3000 kg) to minimize localized feature effects such as graphite fl akes or voids in castings. Common indenters for .

What is indentation hardness testing? The most basic and commonly used definition is the resistance of a material to permanent, plastic deformation. It is measured by loading an . The most common methods used for testing the hardness of metals are Rockwell, Brinell, Vickers, and Knoop. Each of these methods employs different indenters and loads to measure the material’s resistance to plastic .The resulting Rockwell methods use five different indenters (diamond cone with 120 degree curvature or a hard metal ball made of tungsten carbide with diameters: 1/16", 1/8", 1/4", 1/2") and six different total test forces (15, 30, 45, .

Two broad types of tests are used: the Rockwell superficial hardness and the Rockwell regular hardness tests. Brinell: A spherical indenter is used, and the diameter of the resulting indentation is measured to . The most common indenter type is a diamond cone ground at 120 degrees for testing hardened steels and carbides. Softer materials are typically tested using tungsten carbide balls ranging in diameters from 1/16 in .

Get all your information on Rockwell hardness testing from ZwickRoell Definition Advantages and disadvantages Examples More information . The type of indenter (material, shape and size or ball diameter); . the following applies: 1 .Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500; [email protected]; Mon - .The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.

what is indentation testing

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .There are various types of indenters, each designed for specific hardness testing methods and material types. Below are some of the most common types: Diamond Cone: These indenters are mainly used in Rockwell hardness testing. The diamond cone has a tip with an opening angle of 120 degrees and is suitable for very hard materials.Hardness testing indenters come in a whole range of shapes and sizes and correct selection is essential. For example, it is fairly common when measuring the hardness of an armour casting to use a Brinell hardness test because the indenter is a ball. . According to the type of test, different indenters may be used such as a diamond pyramid, a . The most common types of hardness tests are: Rockwell Hardness Test: This test measures the depth of penetration of an indenter into the material. The Rockwell hardness test is the most commonly used hardness test in the industry due to its simplicity and accuracy.

Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500; [email protected]; Mon - Fri: 8:00am - 5:00pm; .Hardness testing is one of the most common quality control checks performed. . Types of Indenters & Test Methods Brinell testing uses larger indenters (e.g. 10 mm) and heavier loads (e.g. 3000 kg) . or shaped pen (Fig. 4) produces a different type of indentation. As shown, the heavy loads produce deeper indentations and

Rockwell superficial scales use lower loads than a regular Rockwell test and are used to test materials too thin or small for the regular scales or outside the normal ranges. Generally, diamond indenters are used for hard materials, while Ball indenters are used for soft materials. These materials often include: Very thin sheet metal; Heavily

Find an answer to your question list the different types of indenters used in hardness testing. RSSS5182 RSSS5182 27.08.2018 Chemistry . Nano-hardness test uses minor loads of about 1 nano-Newton followed by precisemeasuring depth of indentation. Brinell Hardness Test.Rockwell Hardness Test.Rockwell Superficial Hardness Test.Vickers . The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The .

However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials. When selecting which test to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.Hardness testing is widely used in a multitude of . is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. . diamond scale indenters are used on hardened steels and other .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The method can apply with the help of standard test forces and indenters. The load applied in macro hardness tests is of extensive range, starting from 50N to 30000N. . in the micro hardness test, only u one type of indenter is used; A .

what is indentation hardness test

Indentation is the essential phase of various non-cutting methods for determining the hardness of a material. The Brinell hardness test uses a small ball of steel or tungsten carbide to cause the .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .Question: 1. List the 4 different types of harness tests, the types of indenters each uses and the range of loads applied. 2. What is the correlation between hardness (Rockwell) and Tensile Strength for steel? 3. In what situations would you use harness tests instead of a Tensile test?AMETEK makes a variety of Newage indenters and indenter accessories. According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows the use of tungsten carbide ball indenters.

Hardness testing is widely used in a multitude of . is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. . diamond scale indenters are used on hardened steels and other .This part of ISO 6508 specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1:2015, together with a method for verifying Rockwell hardness indenters. The effects of four different sizes of steel and WC ball indenters on different Rockwell hardness scale are studied and compared with the experiments. Both FEA and experimental study provide important quantities reference for the difference of steel and WC indenters in Rockwell hardness tests.

Because of differences between the two types of indenters, it is suspected that the two methods will produce different hardness readings. The metal specimens to be tested are large enough so that two indentions can be made. Therefore, the manufacturer uses both indenters on each specimen and compares the hardness readings.Rockwell Hardness Test. The Rockwell test determines the hardness of a material by measuring the depth of penetration of an indenter under a heavy load compared to the penetration made by a preload method. The Rockwell test has different scales, which are denoted by a single letter, and these use different loads or indenters.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

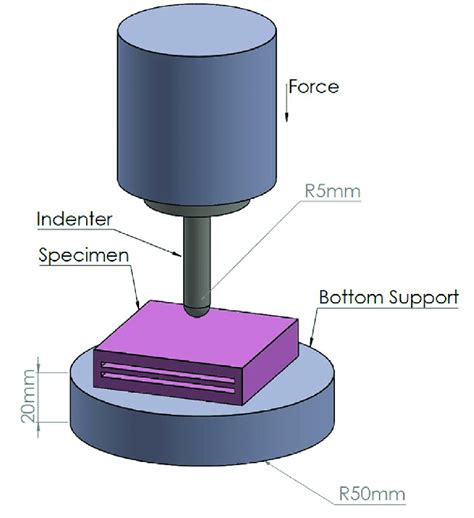

force measurement using universal testing machine

function of load cell in universal testing machine

Lista de sinônimos de resultar. 01. fazer. copiar. explorar. 02. dar. copiar. explorar. 03. produzir. copiar. explorar. 04. conduzir. copiar. explorar. 05. levar. copiar. explorar. 06. .

list the different types of indenters used in hardness testing|what is indentation hardness